MoneyWorks Manual

Bill of Materials (BOM)

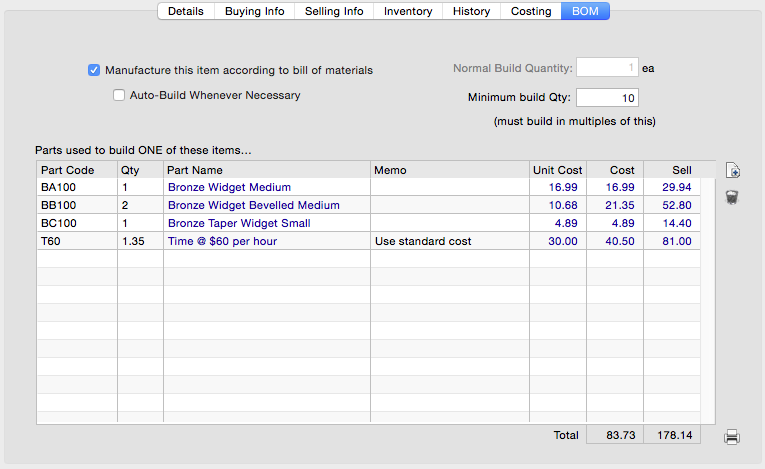

The BOM tab contains information on the components that make up an item that is manufactured.

If you manufacture it

A product can be manufactured from other product items. You can build the product whenever you require it, or it can be automatically built whenever it is sold.

- Set the Manufacture this Item According to Bill of Materials check box

The Recipe list will be enabled.

You need to specify how the item is manufactured. This includes the manufacturing batch size and the components or recipe for the item.

Minimum Build Qty Use the Minimum Build Qty field to specify the number of units that can be physically made at one time. For example an injection moulder may always make comedy plastic noses ten at a time, using 300g of plastic powder. In this case enter 10 into the Minimum Build Qty field. This tells MoneyWorks that it can’t auto-build just (say) three noses, because the nose injection moulder just doesn’t work that way.

Auto-Build Whenever Necessary Set this option if you want MoneyWorks to automatically build the item if it detects there is insufficient in stock to fulfil an order. The item will be built with a Make stock journal—this will be created (and posted) provided there are sufficient components in stock. Note that the margin display on the transaction window is for the old stock—the rebuilt items may have a different cost. If you have volatile component prices and thin margins, it is probably better to use the Build command to create the items so you can better track the actual margin.

Normal Build Qty The Normal Build Qty field contains the normal production run that you would make, and must be a multiple of the Minimum Build Qty. This is the quantity that MoneyWorks will suggest when you use the Build Product command to create a stock transfer to represent a production run. You probably make comedy plastic noses in runs of say 6,000, since the nose injection moulding machine takes a bit of work to set up, and you want to make the effort worthwhile.

- Set the Minimum Build Quantity to the smallest number that can be manufactured

Note: The Minimum Build Quantity is equivalent to the Minimum Order Quantity. You cannot therefore both buy and manufacture the item using different minimum quantities.

- If you want to Auto-Build the item, turn the Auto-Build Whenever Necessary option on

When you sell the item and do not have sufficient stock, MoneyWorks will automatically build the required number based on the bill of materials (even if there is insufficient stock of the components, which will just go into negative stock).

Note: You cannot auto-build items that require a serial or batch number (or whose bill of materials includes serialised products). This is because you need to specify the serial/batch numbers of the items involved at the point the item is manufactured.

Specifying the bill of materials

The bill of materials for the manufactured item is specified in the parts list. The parts in this list must be purchased or stocked1. Thus if you want to include a labour component in your product, that component must have the We Buy This option set.

To add a part to the list:

-

Click the Add button

or press Ctrl-N/⌘-N

or press Ctrl-N/⌘-N

The cursor will be positioned in the next available part row.

- Enter the qty required to build ONE unit, and the part code

The cost and sell fields are automatically filled out for you based on the information in the part’s product record. The part code must be for an existing item that is stocked or purchased.

- If required, enter a memo into the Memo field

This is for your own use, and might be some manufacturing instruction, such as where to position the part. It can be up to 255 characters long.

-

You can remove the current part from the list by clicking the delete button

, or by choosing Delete Part from the Edit menu

, or by choosing Delete Part from the Edit menu

To print the bill of materials:

-

Click the print button

at the bottom right of the list

at the bottom right of the list

The bill of materials is saved when the product record is saved.

Note: The Bill of Materials printout provides a listing of the bill of materials and current costing for a range of products. You can also use the Find Related command to find a product’s components, or what products use this item as a component.

1 This is so that there is a valid cost of goods account for correct cost accounting. ↩